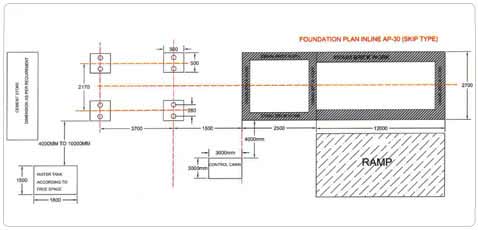

Fully Automatic Concrete Batching & Mixing Plant (IAP Series)

Concrete Batching & Mixing Plant Planetary Mixer Mp 1500/1000

With one mixing star equipped with three arms, with one scaper arms

Cabling and Wiring of Motors and Auxiliary Devices (Limit Switches and Solenoid Valves) to a IP55 Junction Box

Degree IP55, Tropicalised, European Voltage (400V, 50Hz).

Other Voltages are available under request

Solenoid Valves to operate the Discharge Door(s) (Voltage T.B.A.), Four bin feeder Separate weighing for cement, aggregates and sand. Weighing of cement, water, ad-mix and aggregates will be completed simultaneously. Water feeding system by weight. Separate ad-mix dozing by weight.

Belt weighing belt conveyor of 36 feet w/o feeding system. Screw Conveyor For Filling Cement Wam Italy Make.

|

|

Fully Automatic Concrete Batching & Mixing

Plant (IAP Series) |

|

Technical Specification :

| Conveyor Height |

36 feet |

| ValveType |

Solenoid Valves |

| Model/Type |

Mp 1500/1000 |

| Voltage |

400V, 50Hz |

Detailed Data :

| MODEL |

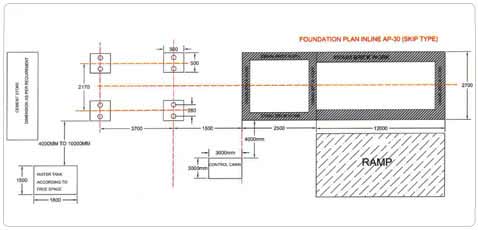

AP-30 (Inline) |

AP-45(Inline) |

| CAPACITY (CUM |

30 |

45 |

| GEO.VOLUME (cum) |

1.7 |

2.5 |

| RMC OUT PUT /BATCH |

0.5 M3 |

0.75 M3 |

| % OF FILLING |

40% |

40% |

| BATCHES PER HOUR |

60 |

60 |

| DISCHARGE HEIGHT FROM G.L |

Discharge in TM. |

Discharge in TM. |

| CAPACITY ( 8 HOURS) |

240 M3 |

360 M3 |

| STORAGE BIN FEEDER |

3 Nos. |

4 Nos. |

| DISCHARGE GATE OPENING |

Reversible |

Hydraulic |

| SYSTEM |

|

|

| POWER CONSUMPTION |

| MIXER MOTOR |

30 HP |

40 HP |

| SKIP MOTOR |

10 HP |

15 HP |

| SCREW FEEDER MOTOR |

15 HP |

15 HP |

| BIN FEEDER MOTOR |

10 HP |

15 HP |

| WATER PUMP |

5 HP |

5 HP |

| COMPRESSOR MOTOR |

3 HP |

5 HP |

| CHEMICAL MOTOR |

1 HP |

1 HP |

| VIBRATOR'S |

2 X 0.5 HP |

2 X 0.5 HP |

| POWER PACK MOTOR |

3 HP |

3 HP |

| NET CONSUMPTION |

83 HP |

105 HP |

| POWER SUPPLY |

415 X 30 50 HZ |

415 X 30 50 HZ |

Technical Features :

- PLC operated completely automatic control panel.

- Blade mixing technology with planetary gear-boxes.

- Electronic weighing system for better accuracy in design –

mix.

- Separate weighing system for cement and fly-ash.

- Italian screw feeder, to pour cement speedily

- Password locking facility

- Water and ad-mix pour by weight.

- Pneumatically weighing system for cement and fly-ash.

- Italian screw feeder to pour cement speedily.

- Password locking facility.

- Water and ad-mix pour by weight.

- Separate Weighting Belt Conveyor.

- Pneumatically operated gate for aggregate and sand.

- Italian vibrators.

- Tabulated print out system for each batch.

- No pit required only nominal civil work.

- Heat proof control cabin.

- Cement silo with vertical screw feeder (optional)

- Hydraulic discharge system.(For Pan Mixer)

- E-mail or SMS facility (optional)

|